Are you a Bluetooth member designing innovative wireless solutions? You may be eligible to participate in the Bluetooth Member Promotion Program.

![]()

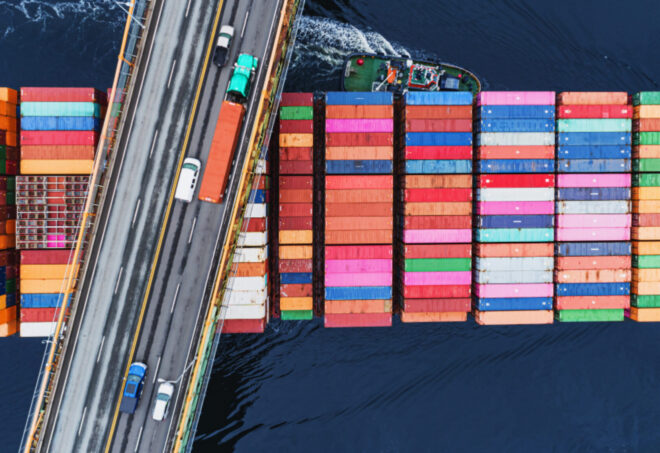

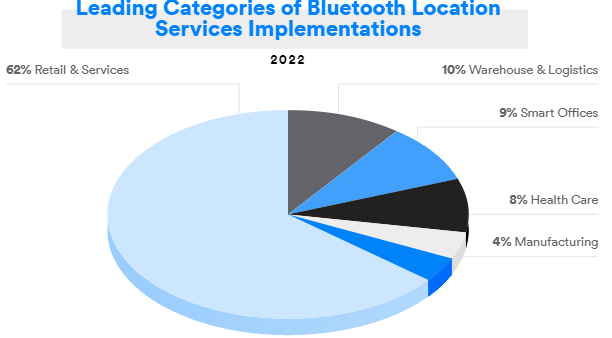

While traditional technologies, like GPS, do not perform well in indoor environments, Bluetooth® technology is tailored for indoor location services. According to the 2019 Bluetooth Market Update, 431 million Bluetooth Location Services devices will ship annually by 2023. That’s 6x growth in annual shipments. The report further forecasts that there will be 1.7 billion handsets (phones, tablets, etc.) actively engaged in Bluetooth location services, making location services the fastest growing Bluetooth solution area.

Recent advancements in Bluetooth specifications introduced greater broadcast data capacity that helps enable richer solutions for beacons and sensor networks to communicate location-specific information. The new Bluetooth Direction Finding feature, released earlier this year, allows you to determine the direction of objects as well as transform location precision from meter-level to centimeter-level accuracy. Moreover, we found location services are being integrated into lighting systems to increase the utility of the automation networks being deployed today.

Recently, I got a chance to talk to WHERE Inc., an associate member company in Japan that provides location information and other IoT solutions. Founded in 2013, they were among the first vendors of location information systems to make use of Bluetooth beacons, and its systems are now operating in many factories and office buildings around the world.

WHERE CEO Hajime Maruta spoke to me about location information service trends, the kind of issues that such services can address, the outlook for future developments in this field, and few examples of real-world use cases and deployments.

Q&A with Hajime Maruta

Which industry is making the most use of WHERE Bluetooth Location Services?

In Japan, location services are growing rapidly, particularly in offices and factories. As an aspect of recent work-style reforms, many companies are starting to use free address systems in their offices, but such systems also present new challenges owing to the difficulty of knowing exactly where employees are at work. Also, in factories, location services can dramatically enhance production management by enabling managers to pinpoint the position of goods-in-process and employees while ascertaining progress status in detail.

Why did you choose Bluetooth technology to develop your solutions?

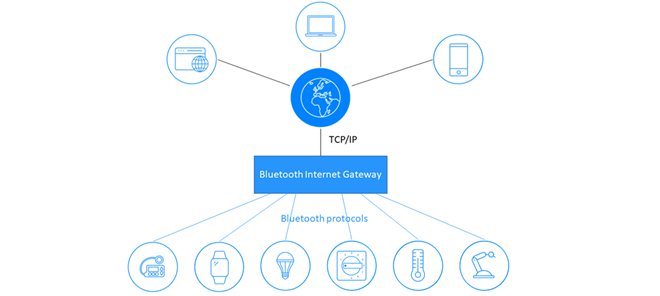

The dedicated IoT Local Area Network that we provide requires not only small-capacity, high-frequency, stable, and low-cost communications but also connectivity with a large number of devices. Enabling such communications with 5G and preceding conventional communication technologies is difficult. Therefore, we decided that Bluetooth® would be the most suitable technology for our demand. We also liked the way that sensors and other terminals could all be connected easily without requiring a global license.

What kind of problems in large-scale facilities can be resolved by location services that use Bluetooth beacons technology? Could you provide any Japanese usage examples?

There are now many examples of full deployment in both offices and factories following the proof-of-concept stage. Let me tell you more about factories using our location information services. In recent years, more and more Japanese companies have been setting up production bases overseas.

Major Automaker Engine Plant

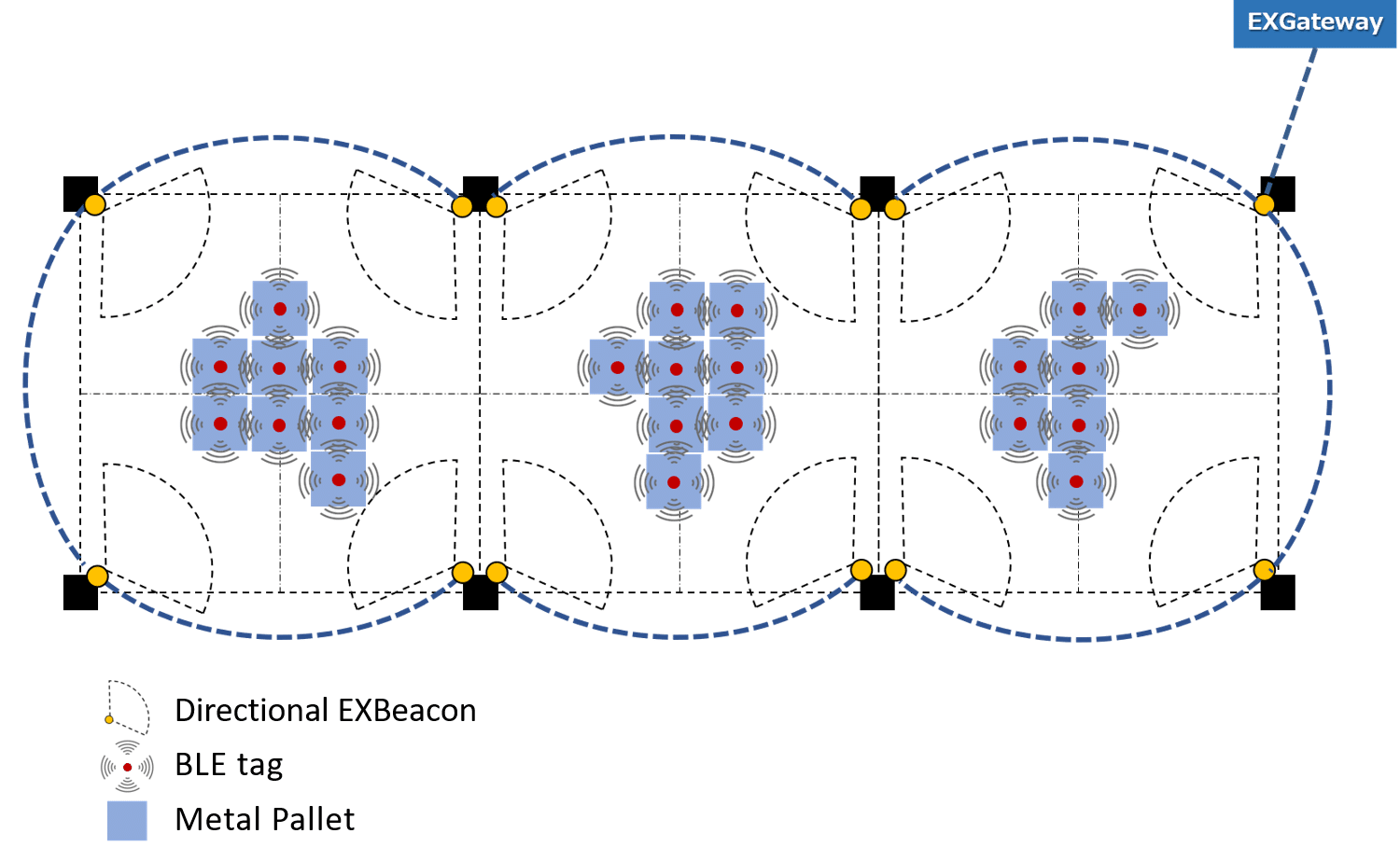

This automaker deployed our EXBeacon Platform, a dedicated IoT LAN, to manage the location of metal pallets, something that it had previously been unable to do. EXBeacon receivers detect radio waves from Bluetooth Low Energy (LE) tags attached to every metal pallet and measure their positions.

Radio positioning is particularly difficult in this case because all the goods-in-process, as well as the pallets, are metal, causing signal reflection. That’s why we used directional EXBeacons (transceivers) equipped with directional antennas. As shown in the schematic below, attaching two-directional EXBeacons on a pillar to determine left and right boundaries enabled more accurate positional pinpointing.

Figure 1: Using EXBeacons to determine pallet locations

Toshiba Elevator Escalator Production Plant

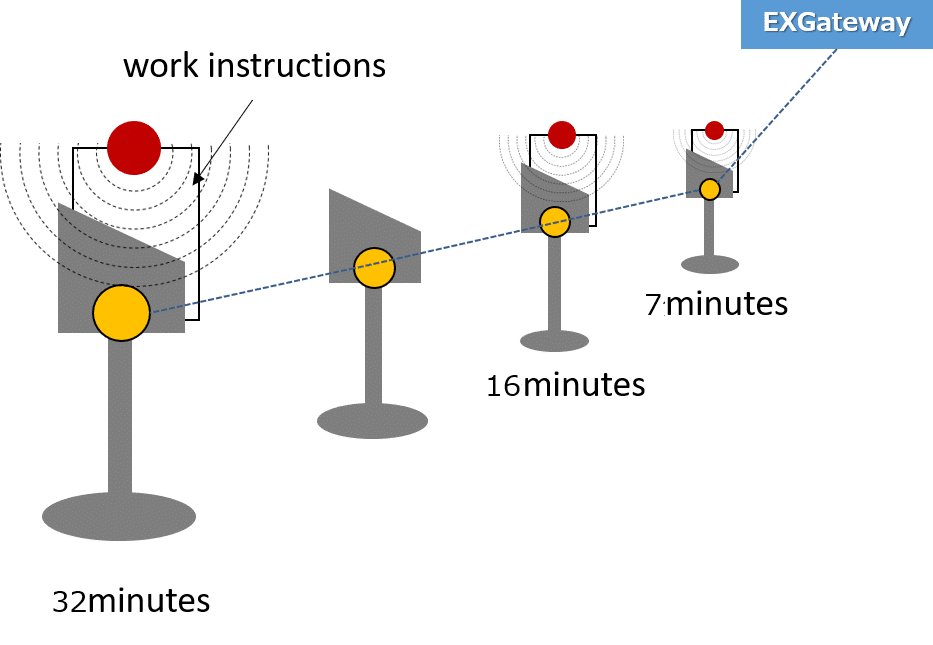

Toshiba Elevator deployed our EXBeacon Platform in the large plant where it assembles escalators to enable more detailed process control than before. The plant not only handles many parts but also produces multiple products simultaneously. Ascertaining which parts of which products had been assembled to what extent had previously been very difficult.

We, therefore, focused on the work ledgers that move with groups of parts, since measuring the position of the ledgers would enable production progress status to be tracked. EXBeacon transceivers attached to ledger racks pick up radio signals from Bluetooth® LE tags attached to each ledger, thereby enabling the position of ledgers to be pinpointed.

Figure 2: Using ledger position to ascertain production progress status

Nakamura Manufacturing (Cutting/Property Processing Technology)

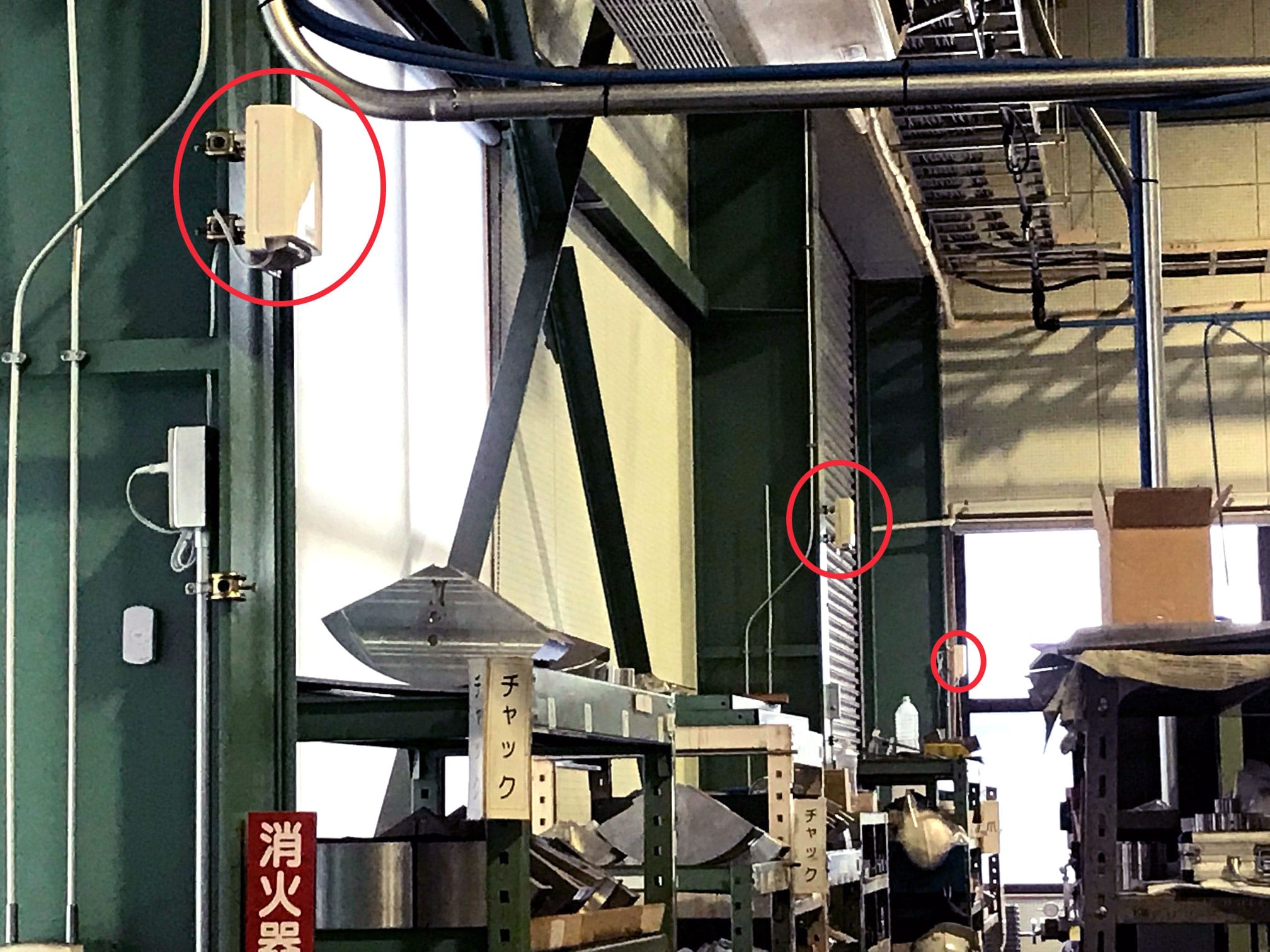

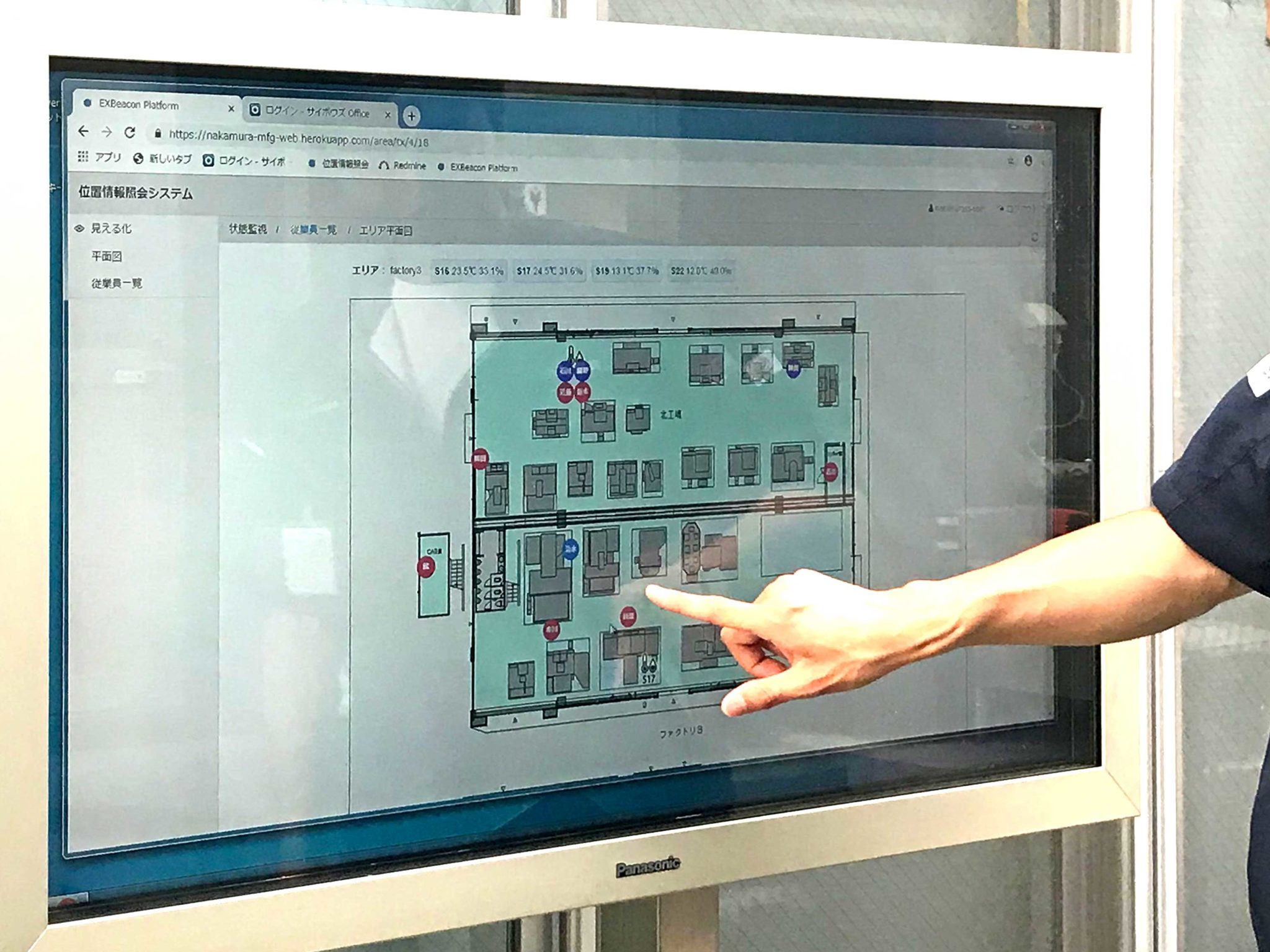

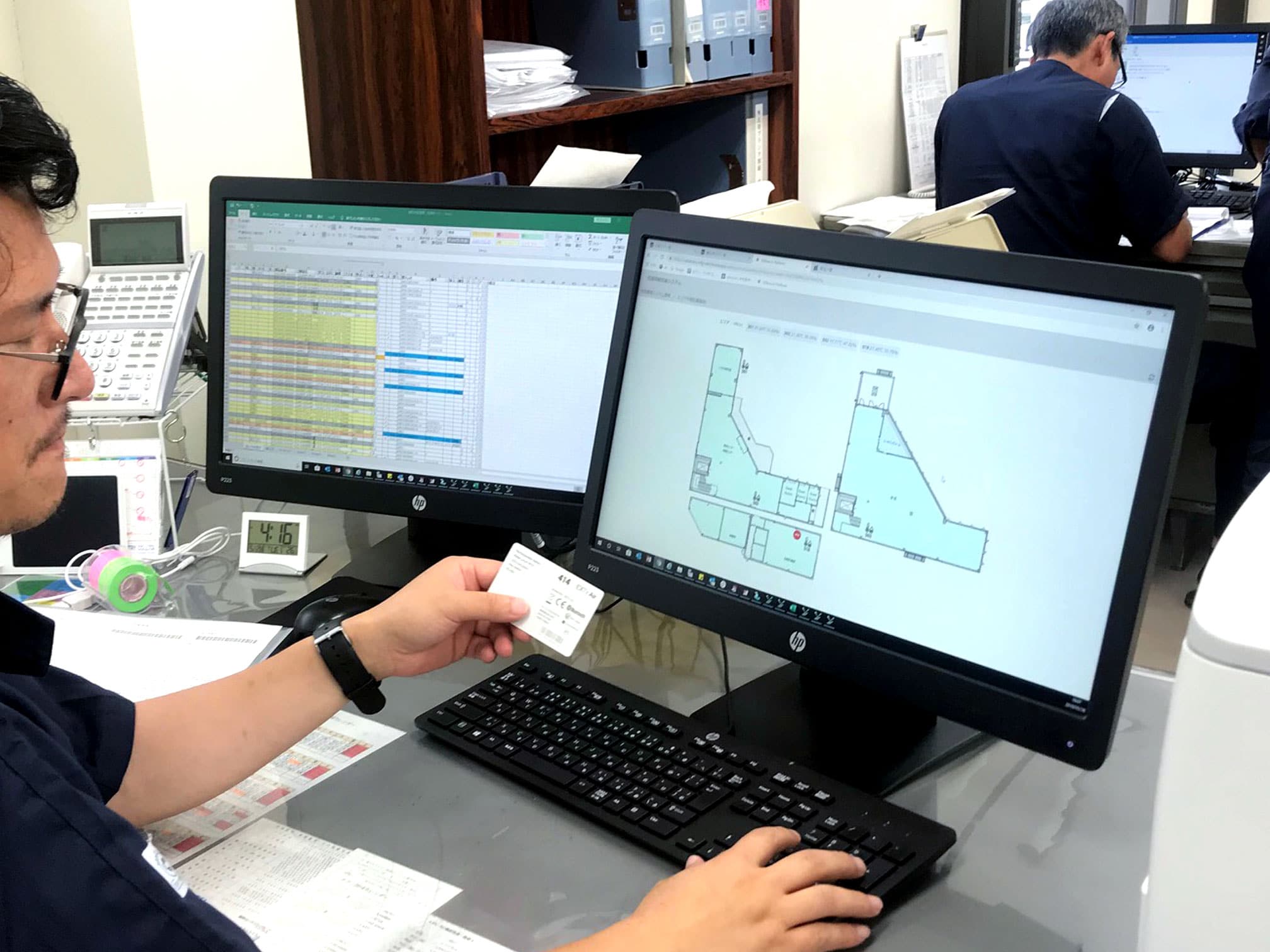

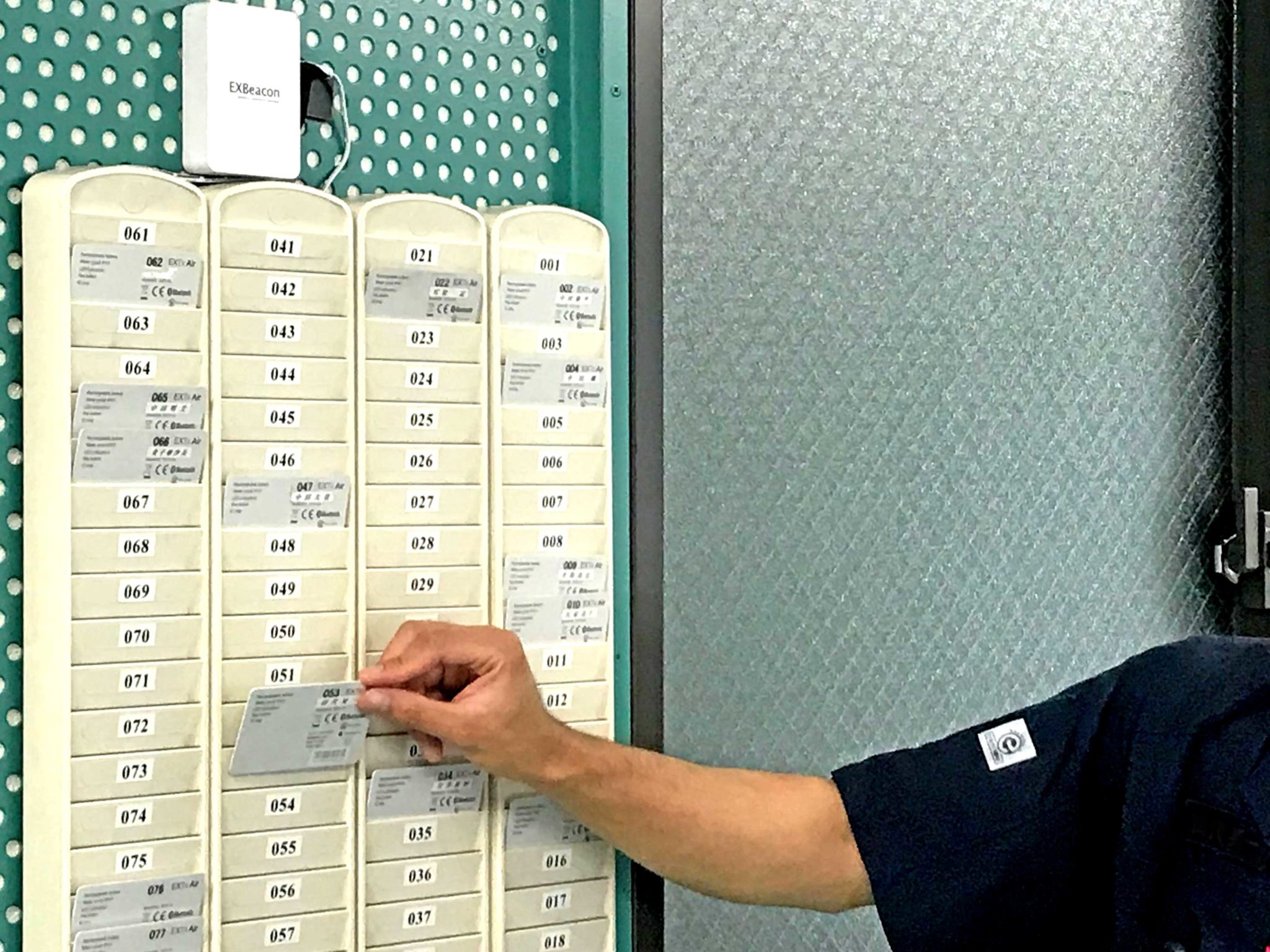

Nakamura Manufacturing deployed our EXBeacon Platform to manage the location of personnel and goods in its precision parts manufacturing plant. Personnel and goods are equipped with ultra-thin, card-type tags whose radio signals are detected by EXBeacon Platform receivers, enabling their locations to be determined.

Figure 3: Placement of EXBeacon receivers enclosed in dust-proof cases

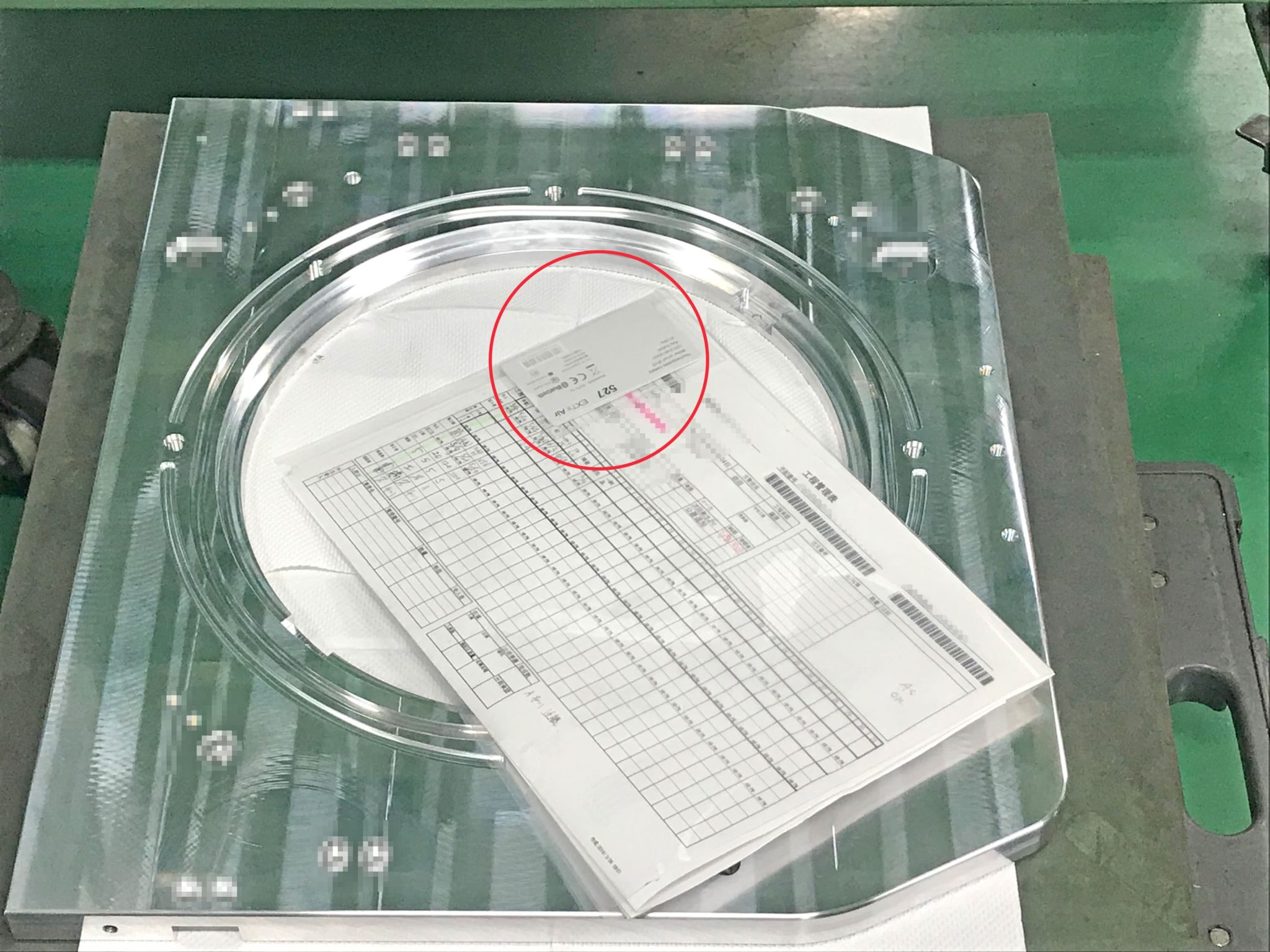

The factory operates around the clock, and, in addition to determining employee locations on the factory premises, the EXBeacon Platform keeps track of employees who have left work, since they clock off by returning their card tags to a dedicated rack. The position of goods-in-process is pinpointed by attaching a card-type tag to the transparent document files used to hold the work management tables (paper) that move with the goods. The EXBeacon Platform is also linked by an API with the higher production management system and constantly provides goods-in-process location and other information, contributing to productivity improvement.

Figure 4. Card-type tag attached work management table document file

Figure 5. Employee location map displayed on an outdoor monitor

Figure 6. Checking the location of goods-in-process on the dashboard

Figure 7. Employee clocking off work by returning his ultra-thin card-type tag to the dedicated rack

What issues are you planning to tackle next?

The number of Bluetooth® LE tags that can be used simultaneously is currently about 10,000. However, with improvements in network performance, we anticipate eventually being able to use over 100,000 tags at the same time. Also, wider use of cloud technology in factories will require tighter security.

In January 2019, the Bluetooth Special Interest Group (SIG) released the new direction finding feature. Will your company leverage the new feature in your coming product roadmap?

I think that the new function in the latest version of the Bluetooth Core Specification for accurately detecting direction and its standardization of the angle of arrival (AoA) and angle of departure (AoD) is great. Finland’s Quuppa was the driving force behind the development of these positioning technologies, and they’re going to be incredibly useful in driving the spread of location services as the technology penetrates the market. We were late getting into it, but we’re also now studying AoA implementation. We also feel that in addition to incorporating individual technologies, Bluetooth mesh should be positioned as a highly influential IoT platform that allows us to create great location services integrated into mesh lighting systems. We believe the Bluetooth SIG will continue to advance the Bluetooth® standard and add new features and capabilities that will help us continue to satisfy our customers’ location services needs.

JOIN THE MEMBER PROMOTION PROGRAM

![Forbes Predictions article 72 dpi 1300 x 680 px 768x402[1]](https://www.bluetooth.com/wp-content/uploads/2024/04/Forbes-Predictions-article-72-dpi-1300-x-680-px-768x4021-1-660x345.png)

![ABI Growth Chart.png 815076338[1]](https://www.bluetooth.com/wp-content/uploads/2024/03/ABI_Growth_Chart.png_8150763381-660x384.png)