-

Revision: v1.0.1

-

Revision Date: 2022-01-18

-

Group Prepared By: Medical Devices Working Group

Revision History

|

Revision Number |

Date |

Comments |

|---|---|---|

|

v1.0 |

2018-07-24 |

Adopted by the Bluetooth SIG Board of Directors. |

|

v1.0.1 |

2022-01-18 |

Adopted by the Bluetooth SIG Board of Directors. |

Version History

|

Versions |

Changes |

|---|---|

|

v1.0 to v1.0.1 |

Incorporated errata E15797, E16486, E17661. |

Acknowledgments

|

Name |

Company |

|---|---|

|

Harald Prinzhorn |

F. Hoffmann-La Roche AG |

|

Leif-Alexandre Aschehoug |

Nordic Semiconductor |

|

Erik Moll |

Koninklijke Philips N.V. |

|

Craig Carlson |

F. Hoffmann-La Roche AG |

|

Nathaniel Hamming |

F. Hoffmann-La Roche AG |

|

Victor Zhodzishsky |

Broadcom Corporation |

|

Wolfgang Heck |

F. Hoffmann-La Roche AG |

|

Christoph Fischer |

F. Hoffmann-La Roche AG |

|

Kris Holtzclaw |

Medtronic Inc. |

Use of this specification is your acknowledgement that you agree to and will comply with the following notices and disclaimers. You are advised to seek appropriate legal, engineering, and other professional advice regarding the use, interpretation, and effect of this specification.

Use of Bluetooth specifications by members of Bluetooth SIG is governed by the membership and other related agreements between Bluetooth SIG and its members, including those agreements posted on Bluetooth SIG’s website located at www.bluetooth.com. Any use of this specification by a member that is not in compliance with the applicable membership and other related agreements is prohibited and, among other things, may result in (i) termination of the applicable agreements and (ii) liability for infringement of the intellectual property rights of Bluetooth SIG and its members. This specification may provide options, because, for example, some products do not implement every portion of the specification. All content within the specification, including notes, appendices, figures, tables, message sequence charts, examples, sample data, and each option identified is intended to be within the bounds of the Scope as defined in the Bluetooth Patent/Copyright License Agreement (“PCLA”). Also, the identification of options for implementing a portion of the specification is intended to provide design flexibility without establishing, for purposes of the PCLA, that any of these options is a “technically reasonable non-infringing alternative.”

Use of this specification by anyone who is not a member of Bluetooth SIG is prohibited and is an infringement of the intellectual property rights of Bluetooth SIG and its members. The furnishing of this specification does not grant any license to any intellectual property of Bluetooth SIG or its members. THIS SPECIFICATION IS PROVIDED “AS IS” AND BLUETOOTH SIG, ITS MEMBERS AND THEIR AFFILIATES MAKE NO REPRESENTATIONS OR WARRANTIES AND DISCLAIM ALL WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTIES OF MERCHANTABILITY, TITLE, NON-INFRINGEMENT, FITNESS FOR ANY PARTICULAR PURPOSE, OR THAT THE CONTENT OF THIS SPECIFICATION IS FREE OF ERRORS. For the avoidance of doubt, Bluetooth SIG has not made any search or investigation as to third parties that may claim rights in or to any specifications or any intellectual property that may be required to implement any specifications and it disclaims any obligation or duty to do so.

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, BLUETOOTH SIG, ITS MEMBERS AND THEIR AFFILIATES DISCLAIM ALL LIABILITY ARISING OUT OF OR RELATING TO USE OF THIS SPECIFICATION AND ANY INFORMATION CONTAINED IN THIS SPECIFICATION, INCLUDING LOST REVENUE, PROFITS, DATA OR PROGRAMS, OR BUSINESS INTERRUPTION, OR FOR SPECIAL, INDIRECT, CONSEQUENTIAL, INCIDENTAL OR PUNITIVE DAMAGES, HOWEVER CAUSED AND REGARDLESS OF THE THEORY OF LIABILITY, AND EVEN IF BLUETOOTH SIG, ITS MEMBERS OR THEIR AFFILIATES HAVE BEEN ADVISED OF THE POSSIBILITY OF THE DAMAGES.

Products equipped with Bluetooth wireless technology ("Bluetooth Products") and their combination, operation, use, implementation, and distribution may be subject to regulatory controls under the laws and regulations of numerous countries that regulate products that use wireless non-licensed spectrum. Examples include airline regulations, telecommunications regulations, technology transfer controls, and health and safety regulations. You are solely responsible for complying with all applicable laws and regulations and for obtaining any and all required authorizations, permits, or licenses in connection with your use of this specification and development, manufacture, and distribution of Bluetooth Products. Nothing in this specification provides any information or assistance in connection with complying with applicable laws or regulations or obtaining required authorizations, permits, or licenses.

Bluetooth SIG is not required to adopt any specification or portion thereof. If this specification is not the final version adopted by Bluetooth SIG’s Board of Directors, it may not be adopted. Any specification adopted by Bluetooth SIG’s Board of Directors may be withdrawn, replaced, or modified at any time. Bluetooth SIG reserves the right to change or alter final specifications in accordance with its membership and operating agreements.

Copyright © 2014–2022. All copyrights in the Bluetooth Specifications themselves are owned by Apple Inc., Ericsson AB, Intel Corporation, Lenovo (Singapore) Pte. Ltd., Microsoft Corporation, Nokia Corporation, and Toshiba Corporation. The Bluetooth word mark and logos are owned by Bluetooth SIG, Inc. Other third-party brands and names are the property of their respective owners.

1. Introduction

The Insulin Delivery Profile is used to enable a device to control an insulin delivery device (IDD) that exposes the Insulin Delivery Service (IDS) [1] and to obtain its status and historical therapy data.

The following table provides an overview of use cases which are considered in the Insulin Delivery Profile and how they are represented by the characteristics and control points (CP) of the Insulin Delivery Service [1]:

|

Use Case |

Insulin Delivery Service Characteristics / CP |

Section |

|---|---|---|

|

Initial Connection (determine supported features of the Insulin Delivery Sensor) |

IDD Features |

|

|

Current Status of Insulin Therapy (provide user with latest therapy relevant information):

|

IDD Status Changed |

|

|

IDD Status |

||

|

IDD Annunciation Status |

||

|

IDD Status Reader CP |

||

|

Supporting Insulin Therapy (defining therapy parameters and accessing historical data):

Access to the history of the Insulin Delivery Sensor using the IDD Record Access Control Point (IDD RACP) |

IDD Command CP |

|

|

IDD Command Data |

||

|

IDD RACP |

||

|

IDD History Data |

||

|

Remote Operation of Insulin Therapy (remote control of the Insulin Delivery Sensor):

|

IDD Command CP |

|

|

Remote Operation for Device Maintenance (extends the remote operation of insulin therapy):

|

1.1. Profile dependencies

This Profile requires the Generic Attribute Profile (GATT).

1.2. Conformance

If conformance to this specification is claimed, all capabilities indicated as mandatory for this specification shall be supported in the specified manner (process-mandatory). This also applies for all optional and conditional capabilities for which support is indicated.

1.3. Language

1.3.1. Language conventions

The Bluetooth SIG has established the following conventions for use of the words shall, must, will, should, may, can, is, and note in the development of specifications:

|

shall |

is required to – used to define requirements. |

|

must |

is a natural consequence of – used only to describe unavoidable situations. |

|

will |

it is true that – only used in statements of fact. |

|

should |

is recommended that – used to indicate that among several possibilities one is recommended as particularly suitable, but not required. |

|

may |

is permitted to – used to allow options. |

|

can |

is able to – used to relate statements in a causal manner. |

|

is |

is defined as – used to further explain elements that are previously required or allowed. |

|

note |

Used to indicate text that is included for informational purposes only and is not required in order to implement the specification. Each note is clearly designated as a “Note” and set off in a separate paragraph. |

For clarity of the definition of those terms, see Core Specification Volume 1, Part E, Section 1.

Certain terms used in this specification have been updated and are no longer used by Bluetooth SIG. For a list of terms that have been updated and their replacement terms, see the Appropriate Language Mapping Table [15].

1.3.2. Reserved for Future Use

Where a field in a packet, Protocol Data Unit (PDU), or other data structure is described as "Reserved for Future Use" (irrespective of whether in uppercase or lowercase), the device creating the structure shall set its value to zero unless otherwise specified. Any device receiving or interpreting the structure shall ignore that field; in particular, it shall not reject the structure because of the value of the field.

Where a field, parameter, or other variable object can take a range of values, and some values are described as "Reserved for Future Use," a device sending the object shall not set the object to those values. A device receiving an object with such a value should reject it, and any data structure containing it, as being erroneous; however, this does not apply in a context where the object is described as being ignored or it is specified to ignore unrecognized values.

When a field value is a bit field, unassigned bits can be marked as Reserved for Future Use and shall be set to 0. Implementations that receive a message that contains a Reserved for Future Use bit that is set to 1 shall process the message as if that bit was set to 0, except where specified otherwise.

The acronym RFU is equivalent to Reserved for Future Use.

1.3.3. Prohibited

When a field value is an enumeration, unassigned values can be marked as “Prohibited.” These values shall never be used by an implementation, and any message received that includes a Prohibited value shall be ignored and shall not be processed and shall not be responded to.

Where a field, parameter, or other variable object can take a range of values, and some values are described as “Prohibited,” devices shall not set the object to any of those Prohibited values. A device receiving an object with such a value should reject it, and any data structure containing it, as being erroneous.

“Prohibited” is never abbreviated.

1.4. Bluetooth Specification release compatibility

This specification is compatible with any Bluetooth Core Specification [9] that includes the Generic Attribute Profile (GATT).

2. Configuration

2.1. Roles

The profile defines two roles: Insulin Delivery Sensor and Collector. The Insulin Delivery Sensor is the device that runs an insulin infusion therapy and provides therapy and status data and the Collector is the device that receives this data. In addition, the Collector can send data to the Sensor for configuration or control purposes.

-

The Insulin Delivery Sensor shall be a GATT Server.

-

The Collector shall be a GATT Client.

At any given time an Insulin Delivery Sensor shall be connected to only one Collector.

2.2. Role/Service relationships

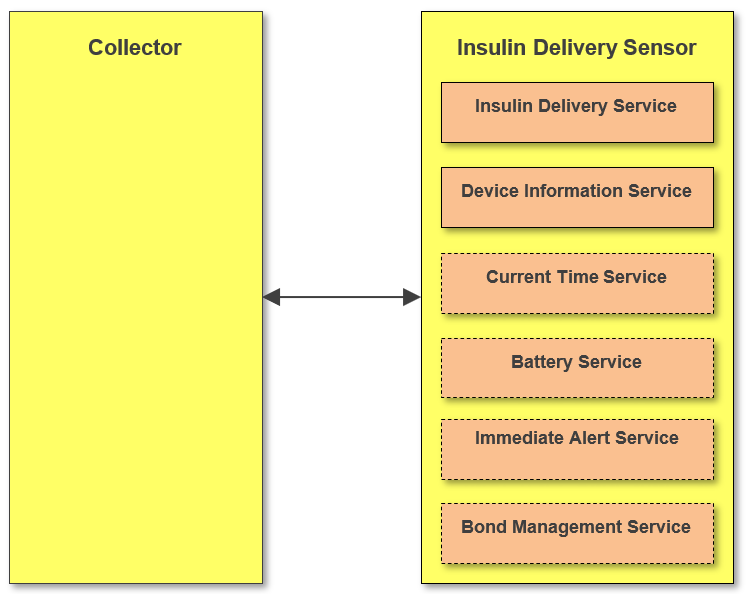

The following diagram shows the relationships between services and the profile roles.

|

Note

Note: Profile roles are represented by yellow boxes and services are represented by orange boxes. Services in dotted boxes are optionally instantiated.

An Insulin Delivery Sensor instantiates the Insulin Delivery Service [1], Device Information Service [2], and optionally the Current Time Service [3], Battery Service [4], Immediate Alert Service [5], and also optionally the Bond Management Service (BMS) [6].

2.3. Concurrency limitations and restrictions

If a Sensor is in connection, it shall be connected to only one Collector and there shall be no data broadcasts to multiple Collectors.

2.4. Topology limitations and restrictions

2.4.1. Topology limitations and restrictions for Low Energy

This section describes topology limitations and restrictions when the profile is to be used over Low Energy transport.

The Insulin Delivery Sensor shall use the GAP Peripheral role and may implement the GAP Central role.

The Collector shall use the GAP Central role and may implement the GAP Peripheral role.

2.5. Transport dependencies

This profile shall operate over an LE transport only. For BR/EDR (and HS) the Health Device Profile [8] is to be used. This is to avoid having two ways to send insulin delivery data over a BR/EDR transport.

3. Insulin Delivery Sensor role requirements

The Insulin Delivery Sensor shall support the GATT server role and instantiate one and only one Insulin Delivery Service [1] and one Device Information Service [2]. The Insulin Delivery Sensor may also instantiate one Current Time Service [3], one Battery Service [4], one Immediate Alert Service [5], and conditionally one Bond Management Service [6].

|

Service |

Insulin Delivery Sensor |

||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Insulin Delivery Service |

M |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Device Information Service |

M |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Current Time Service |

O[a] |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Battery Service |

O |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Immediate Alert Service |

O |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Bond Management Service |

C.1 |

||||||||||||||||||||||||||||||||||||||||||||||||

- C.1:

-

Mandatory if multiple bonds are supported, otherwise optional.

See Section 5.1 and Section 6.1 for additional requirements for the Insulin Delivery Sensor role.

3.1. Incremental Insulin Delivery Service requirements

3.1.1. Writable GAP Device Name characteristic

The Insulin Delivery Sensor may support the write property for the Device Name characteristic in order to allow a Collector to write a device name to the Insulin Delivery Sensor.

3.1.2. Additional requirements for Low Energy transport

This section describes additional Insulin Delivery Sensor requirements and recommendations beyond those defined in the Insulin Delivery Service when using this profile over Low Energy transport.

The following requirements that imply the inclusion of the device name or unique data in the Advertising or Scan Response Data should not apply if the Link Layer Privacy is used as specified in Bluetooth Core Specification v4.2 [14] or later.

3.1.2.1. Service UUIDs AD Type

While in a GAP Discoverable Mode for initial connection to a Collector, the Insulin Delivery Sensor should include the Insulin Delivery Service UUID defined in [10] in the Service UUID’s AD type field of the Advertising Data. This enhances the user experience as an Insulin Delivery Sensor may be identified by the Collector before initiating a connection.

3.1.2.2. Local Name AD Type

For an enhanced user experience, an Insulin Delivery Sensor should include the Local Name (containing either the complete or shortened value of the Device Name characteristic as defined in [9]) in its Advertising Data or Scan Response Data.

3.1.2.3. Appearance AD Type

For an enhanced user experience, an Insulin Delivery Sensor should include the value of the Appearance characteristic defined in [2] in its Advertising data or Scan Response data.

In the following sections, the words a “Target Address AD Type” are intended to refer to either of the defined Target Address AD Types.

3.2. Incremental Device Information Service requirements

The table below shows additional requirements and recommendations beyond those defined in the Device Information Service.

|

Device Information Service Characteristics |

Requirement |

|---|---|

|

Manufacturer Name String |

M |

|

Model Number String |

M |

|

System ID |

M |

Characteristics in this service may be transcoded by the Collector for use in an ISO/IEEE 11073 ecosystem. See the Personal Health Devices Transcoding White Paper [11] for more information. Since strings in this service are encoded as UTF-8, and ISO/IEEE 11073-20601a [12] specifies that strings are encoded as ASCII printable characters (a subset of UTF-8), characters used in string characteristics that are to be transcoded for use in an ISO/IEEE 11073 ecosystem shall be restricted to the printable ASCII character set.

If the ISO/IEEE 11073-20601 specification is updated in the future to include UTF-8 support, implementers should consider the impact of using non-ASCII characters on backward compatibility.

Note

Note: The Personal Health Devices Transcoding White Paper [11] recommends that characters outside of the printable ASCII range are translated to characters inside of the printable ASCII range as appropriate.

3.3. Incremental Bond Management Service requirements

Authorization codes shall be mandatory for all supported Bond Management Control Point (BMCP) procedures (see [6]).

4. Collector role requirements

The Collector role shall support the Insulin Delivery Service [1] and may support the Device Information Service [2], Current Time Service [3] according to the Time Profile [7], Battery Service [4], Immediate Alert Service [5], and Bond Management Service [6] on the GATT server.

|

Service |

Collector |

||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Insulin Delivery Service |

M |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Device Information Service |

O |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Current Time Service |

O[a] |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Battery Service |

O |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Immediate Alert Service |

O |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Bond Management Service |

O |

||||||||||||||||||||||||||||||||||||||||||||||||

This section describes the profile requirements for a Collector.

|

Profile Requirement |

Section |

Support in Collector |

|---|---|---|

|

Service Discovery |

M |

|

|

Characteristic Discovery |

M |

|

|

IDD Status Changed |

M |

|

|

IDD Status |

M |

|

|

IDD Annunciation Status |

M |

|

|

IDD Features |

M |

|

|

IDD Status Reader Control Point |

M |

|

|

IDD Command Control Point |

O |

|

|

IDD Command Data |

C.1 |

|

|

IDD Record Access Control Point |

O |

|

|

IDD History Data |

C.2 |

|

|

Bond Management Control Point |

C.3 |

|

|

Bond Management Feature |

C.3 |

- C.1:

-

Mandatory if optional IDD Command Control Point is supported, otherwise excluded

- C.2:

-

Mandatory if optional IDD Record Access Control Point is supported, otherwise excluded.

- C.3:

-

Mandatory if Bond Management Service is supported, otherwise excluded.

4.1. GATT sub-procedure requirements

Requirements in this section represent a minimum set of requirements for a Collector (Client). Other GATT sub-procedures may be used if supported by both Client and Server.

The table below summarizes additional GATT sub-procedure requirements beyond those required by all GATT Clients.

|

GATT Sub-Procedure |

Collector (Client) Requirements |

|---|---|

|

Discover All Primary Services |

C.1 |

|

Discover Primary Services by Service UUID |

C.1 |

|

Discover All Characteristics of a Service |

C.2 |

|

Discover Characteristics by UUID |

C.2 |

|

Discover All Characteristic Descriptors |

M |

|

Notifications |

M |

|

Indications |

M |

|

Read Characteristic Value |

M |

|

Write Characteristic Value |

M |

|

Reliable Writes |

C.3 |

|

Write Long Characteristic Values |

C.3 |

|

Write Without Response |

C.4 |

|

Read Characteristic Descriptors |

M |

|

Write Characteristic Descriptors |

M |

- C.1:

-

Mandatory to support at least one of these service discovery sub-procedures.

- C.2:

-

Mandatory to support at least one of these characteristic discovery sub-procedures.

- C.3:

-

Mandatory if Bond Management Service is supported, otherwise optional.

- C.4:

-

Mandatory if Immediate Alert Service is supported, otherwise optional.

4.2. Service discovery

The Collector shall use the GATT Service Discovery to discover the services according to Section 4.

The Collector shall perform primary service discovery using either the GATT Discover All Primary Services sub-procedure or the GATT Discover Primary Services by Service UUID sub-procedure.

4.3. Characteristic discovery

As required by GATT, the Collector shall be tolerant of additional optional characteristics in the service records of services used with this profile.

The Collector shall perform either the GATT Discover All Characteristics of a Service sub-procedure or the GATT Discover Characteristics by UUID sub-procedure in order to discover the characteristics of the services of this profile.

The Collector shall perform the GATT Discover All Characteristic Descriptors sub-procedure in order to discover the Client Characteristic Configuration Descriptors.

The profile requirements concerning the discovery of the Characteristics also apply to the discovery of their Client Characteristic Configuration Descriptors according to Table 4.4.

|

Profile Requirement |

Support in Collector |

||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Insulin Delivery Service Characteristic Discovery |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

M |

||||||||||||||||||||||||||||||||||||||||||||||||

|

M |

||||||||||||||||||||||||||||||||||||||||||||||||

|

M |

||||||||||||||||||||||||||||||||||||||||||||||||

|

M |

||||||||||||||||||||||||||||||||||||||||||||||||

|

M |

||||||||||||||||||||||||||||||||||||||||||||||||

|

O |

||||||||||||||||||||||||||||||||||||||||||||||||

|

C.1 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

O |

||||||||||||||||||||||||||||||||||||||||||||||||

|

C.2 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Device Information Service Characteristic Discovery |

O |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Current Time Service Characteristic Discovery |

O[a] |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Battery Service Characteristic Discovery |

O |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Immediate Alert Service Characteristics Discovery |

O |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Bond Management Service Characteristic Discovery |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

C.3 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

C.3 |

||||||||||||||||||||||||||||||||||||||||||||||||

- C.1:

-

Mandatory if optional IDD Command Control Point is supported, otherwise excluded.

- C.2:

-

Mandatory if optional IDD Record Access Control Point is supported, otherwise excluded.

- C.3:

-

Mandatory if Bond Management Service is supported, otherwise excluded.

4.4. Common Insulin Delivery Service characteristic requirements

If the Insulin Delivery Sensor supports (End-to-End-Protection) E2E-Protection (E2E-Protection Supported bit is set in Flags field of IDD Features, see Section 4.9), the Collector shall increment the value of the E2E-Counter field, hereafter referred to as the transmit E2E-Counter value, of an accessed control point with each write request to that control point.

If the Collector supports E2E-Protection, it shall check if the received E2E-Counter value within the E2E‑Counter field was increased since the last access of a specific characteristic (i.e., the Insulin Delivery Sensor manages its own transmit E2E-Counter values for each characteristic). For additional details, see Section 4.15.1.1. In addition, it shall check the validity of the fields of a characteristic by checking the value of the E2E-CRC field calculated over all fields including the E2E-Counter field (see Section 1.8 in [1] for more details about E2E-Protection).

4.5. Receiving changes of the status of the insulin therapy

There are two ways that a Collector can receive changes of the insulin therapy (also see this use case Section 1):

Automatic:

Typically the Collector and the Insulin Delivery Sensor are in connection during the therapy session. So, changes are transmitted as soon as they occur if the corresponding Client Characteristic Descriptor is configured for indications. In this way, either the IDD Status Changed characteristic (see Section 4.6 ) can be indicated and then the Collector can read all relevant characteristics holding status values (e.g., IDD Status) and execute CP procedures (e.g., procedure Get Active Basal Rate Delivery of IDD Status Reader CP) or these characteristics can be configured for indications directly.

On demand:

Whenever the Collector requires updated status information, it can read the IDD Status Changed characteristic and then read all relevant characteristics or execute CP procedures providing status values (see Section 10 and Section 3.2.1.3 in [1]).

4.6. IDD Status Changed characteristic

The Collector may read the IDD Status Changed characteristic to determine status changes of the Insulin Delivery Sensor (concerning the insulin therapy and the insulin delivery device) since the last status reset performed by the Reset Status procedure of the IDD Status Reader Control Point (see Section 4.10.2).

The Collector may actively read the IDD Status Changed characteristic after reconnection or may configure the IDD Status Changed characteristic for indications to receive status changes as soon as they are raised by the Insulin Delivery Sensor.

4.7. IDD Status characteristic

The Collector may read the IDD Status characteristic to receive status values of the Insulin Delivery Sensor (concerning the insulin therapy and the insulin delivery device).

The Collector may read the status values from the IDD Status characteristic after getting a device status change signaled by one of the following bits of the Flags field of the IDD Status Changed characteristic (see Section 4.6):

-

Therapy Control State Changed

-

Operational State Changed

-

Reservoir Status Changed

The Collector may configure the IDD Status characteristic for indications to receive changed status values as soon as they are raised by the higher layer application on the Insulin Delivery Sensor (Insulin Delivery Sensor Application) that instantiates the Insulin Delivery Service (for details see Section 4.5).

4.8. IDD Annunciation Status characteristic

The Collector may read the IDD Annunciation Status characteristic to receive messages, which describe state changes of the insulin delivery device in the therapy relevant functions.

The Collector may read the status values from the IDD Annunciation Status characteristic after getting an annunciation status change signaled by the following bit of the Flags field of the IDD Status Changed characteristic (see Section 4.6):

-

Annunciation Status Changed

The Collector may also configure the IDD Annunciation Status characteristic for indications to receive changed status values as soon as they are raised by the Insulin Delivery Sensor Application (for details see Section 4.5).

4.9. IDD Features characteristic

To determine the supported features of the Insulin Delivery Sensor, the Collector shall read the IDD Features characteristic.

If the IDD Features characteristic supports indications, the Collector may configure this characteristic for indications. When the Collector receives an indication of the IDD Features characteristic, the Collector shall use the indicated value to determine the supported features again. Alternatively, the Collector may read the IDD Features characteristic each time after connecting with the Insulin Delivery Sensor. A Collector shall enable indications of the IDD Features characteristic, or it shall read the IDD Features characteristic on each connection.

The Insulin Concentration field may be used by the Collector to determine the intended insulin concentration of the insulin delivery device in International Units per milliliters (IU/mL).

The Flags field contains the following feature bits:

-

If the E2E-Protection Supported bit is set to 1, all characteristics except the IDD History Data characteristic contain an E2E-Counter field and an E2E-CRC field (IDD History Data contains the E2E-CRC field but no E2E-Counter field). In that case the Collector shall use an appropriate transmit E2E-Counter value and shall calculate the CRC if it writes to a characteristic (see Section 4.4). Otherwise the Server responds with an E2E-error (for details see Section 3.12 in [1]). The Collector may check the received E2E-Counter value and E2E-CRC if it reads a characteristic, receives notification or indications (for details see Section 4.16).

-

If the Basal Rate Supported bit is set to 1, the Collector can determine that the Insulin Delivery Sensor supports the delivery of a basal rate and also basal rate profile templates that are templates of programmed series of basal rates in the context of the insulin infusion therapy.

-

If the TBR Absolute Supported bit is set to 1, the Collector can determine that the Insulin Delivery Sensor supports an absolute temporary basal rate in International Unit per hour (IU/h).

-

If the TBR Relative Supported bit is set to 1, the Collector can determine that the Insulin Delivery Sensor supports a relative temporary basal expressed by a dimensionless scaling factor.

-

If the TBR Template Supported bit is set to 1, the Collector can determine that the Insulin Delivery Sensor supports templates to define different kinds of Temporary Basal Rates (TBR). In this case the Collector Application can provide one or more templates with TBR settings, which can be selected by the user.

-

If the Fast Bolus Supported bit is set to 1, the Collector can determine that the Insulin Delivery Sensor supports the delivery of fast boluses.

-

If the Extended Bolus Supported bit is set to 1, the Collector can determine that the Insulin Delivery Sensor supports the delivery of extended boluses.

-

If the Multiwave Bolus Supported bit is set to 1, the Collector can determine that the Insulin Delivery Sensor supports the delivery of multiwave boluses.

-

If the Bolus Delay Time Supported bit is set to 1, the Collector can determine that the Insulin Delivery Sensor supports a bolus delay time. In this case the Collector can attach a Bolus Delay Time in the parameters of the Set Bolus procedure (see Section 4.11.2.13) is executed.

-

If the Bolus Template Supported bit is set to 1, the Collector can determine that the Insulin Delivery Sensor supports templates to define different kinds of boluses. In this case the Collector Application can provide one or more templates with bolus settings which can be selected by the user.

-

If the Bolus Activation Type Supported bit is set to 1, the Collector can determine that the Insulin Delivery Sensor supports a bolus activation type, which provides additional information about the source and, as possible, the determination of the bolus amount. In this case the Collector can attach a Bolus Activation Type in the parameters of the Set Bolus procedure (see Section 4.11.2.13) is executed.

-

If the Multiple Bond Supported bit is set to 0, the Collector can determine that the Insulin Delivery Sensor supports only a single bond. Otherwise the Collector can determine that the Insulin Delivery Sensor supports multiple bonds.

-

If the ISF Profile Template Supported bit is set to 1, the Collector can determine that the Insulin Delivery Sensor supports ISF profiles and also templates to define different kinds of ISF profiles. In this case the Collector Application can provide one or more templates with ISF settings, which can be selected by the user. An ISF profile can be considered in the calculation of a bolus calculator of the Sensor or Collector Application.

-

If the I2CHO Ratio Profile Template Supported bit is set to 1, the Collector can determine that the Insulin Delivery Sensor supports I:CHO Ratio profiles and also templates to define different kinds of I:CHO Ratio profiles. In this case the Collector Application can provide one or more templates with I:CHO Ratio settings, which can be selected by the user. An I:CHO Ratio profile can be considered in the calculation of a bolus calculator of the Sensor or Collector Application.

-

If the Target Glucose Range Profile Template Supported bit is set to 1, the Collector can determine that the Insulin Delivery Sensor supports target glucose range profiles and also templates to define different kinds of target glucose range profiles. In this case the Collector Application can provide one or more templates with target glucose range settings, which can be selected by the user. A target glucose range profile can be considered in the calculation of a bolus calculator of the Sensor or Collector Application.

-

If the Insulin On Board Supported bit is set to 1, the Collector can determine that the Insulin Delivery Sensor provides the current Insulin on Board (IOB). The IOB can be considered in the calculation of a bolus calculator of the Sensor or Collector Application.

-

If the Feature Extension bit is set to 1, the Collector can determine that an additional octet is attached (bits 24 … 31), where bit 31 is used as Feature Extension bit in the same way. If this bit is set, then another octet is attached (bits 32 … 39) and so on.

If one of the feature bits above is set to False and the Collector executes a procedure in the following cases, it shall be able to handle the following Response Code Values in the Operand set to:

-

Op Code not supported if the Op Code of the procedure is mandatory for that feature (e.g., Basal Rate Supported bit is set to 0 and the Collector executes the Get Active Basal Rate Delivery procedure)

-

Invalid Operand if at least one field value in the Operand requires that feature (e.g., Extended Bolus Supported bit is set to 0 and the Collector executes the Set Bolus procedure with a Bolus Type field with value Extended in the Operand)

(See Section 3.12.4 in [1].)

4.10. IDD Status Reader Control Point

Before performing an IDD Status Reader Control Point procedure, the Collector shall configure the IDD Status Reader Control Point characteristic for indications (i.e., by writing to the Client Characteristic Configuration descriptor).

4.10.1. IDD Status Reader Control Point procedure requirements

Table 4.5 shows the requirements for the IDD Status Reader control point procedures (Op Codes):

|

Procedure (Op Code) |

Section |

Requirements |

|---|---|---|

|

Reset Status |

M |

|

|

Get Active Bolus IDs |

C.1 |

|

|

Get Active Bolus Delivery |

C.1 |

|

|

Get Active Basal Rate Delivery |

C.2 |

|

|

Get Total Daily Insulin Status |

M |

|

|

Get Counter |

O |

|

|

Get Delivered Insulin |

O |

|

|

Get Insulin On Board |

C.3 |

- C.1:

-

Mandatory if boluses are supported, otherwise excluded.

- C.2:

-

Mandatory if a basal rate is supported, otherwise excluded.

- C.3:

-

Mandatory if insulin on board is supported, otherwise excluded.

4.10.2. IDD Status Reader Control Point behavioral description

4.10.2.1. Reset Status procedure

To reset a status exposed by the IDD Status Changed characteristic, the Collector shall write the Reset Status Op Code followed by a Flags field as defined in the IDD Status Changed characteristic to the IDD Status Reader Control Point.

The Collector shall wait for the Response Code Op Code indication with Response Code Value set to Success indicating success of the operation as per the request or an error value as described in Section 4.15.5.

To get further updates by changes of the Flags field of the IDD Status Changed characteristic, the Collector shall use this procedure (for details see Section 4.6).

If a bit of the Flags Operand is set to 1, the Server will reset the corresponding status of the IDD Status Changed characteristic by setting it to 0. If a bit of the Flags Operand is set to 0, the status will be retained.

Typically the Collector is informed about status changes of the Insulin Delivery Sensor by evaluating the IDD Status Changed Flags field (e.g., Therapy Control State Changed bit set). Then the Collector reads the relevant status values (e.g., IDD Status characteristic) and finally informs the Insulin Delivery Sensor about the completed evaluation and processing by executing the Reset Status.

4.10.2.2. Get Active Bolus IDs procedure

To get the IDs of the potential seven current active boluses, the Collector shall write the Get Active Bolus IDs Op Code to the IDD Status Reader Control Point.

The Collector shall wait for the Get Active Bolus IDs Response Op Code indication with an Active Bolus ID record indicating success of the operation as per the request or a Response Code Op Code indication with an error value as described in Section 4.15.5.

The Active Bolus ID record contains the Bolus IDs of the active boluses in the order of their start time (i.e., the Bolus ID1 field contains the ID of the oldest bolus and the Bolus ID7 field the ID of the latest delivered bolus).

If the Insulin Delivery Sensor responds with a Number of Active Boluses being more than 7, the 7 Active Bolus ID fields refer to the ones with the oldest start date time. In this case the Collector may use the IDD RACP (see Section 4.13) to retrieve information about the programmed boluses by reading the Bolus Programmed Events. However this is assumed as an exceptional case.

The Collector can use this procedure after receiving an active bolus status change signaled by the Active Bolus Status Changed bit of the Flags field of the IDD Status Changed characteristic (see Section 4.6).

To get the details about a currently active bolus, the Collector shall use the Get Active Bolus Delivery procedure with the associated bolus ID.

4.10.2.3. Get Active Bolus Delivery procedure

To get delivery information about a specific active bolus, the Collector shall write the Get Active Bolus Delivery Op Code followed by a Bolus ID and a desired Bolus Value Selection to the IDD Status Reader Control Point. The Bolus Value Selection Operand specifies if the programmed, remaining (e.g., remaining insulin amount) or delivered values (e.g., already delivered insulin amount) are returned in the response of this procedure.

The Collector shall wait for the Get Active Bolus Delivery Response Op Code indication with an Active Bolus Delivery record indicating success of the operation as per the request or a Response Code Op Code indication with an error value as described in Section 4.15.5.

The Collector can use this procedure after receiving an active bolus status change signaled by the Active Bolus Status Changed bit of the Flags field of the IDD Status Changed characteristic (see Section 4.6).

The Collector shall be able to handle a Bolus Delay Time of 0xFFFF in the response if the Bolus Value Selection Operand is set to Delivered, which means that the Bolus Delay Time is not applicable with that Bolus Value Selection Operand.

4.10.2.4. Get Active Basal Rate Delivery procedure

To get the active basal rate setting including the TBR, the Collector shall write the Get Active Basal Rate Delivery Op Code to the IDD Status Reader Control Point.

The Collector shall wait for the Get Active Basal Delivery Response Op Code indication with an Active Basal Delivery record indicating success of the operation as per the request or a Response Code Op Code indication with an error value as described in Section 4.15.5.

The Collector can use this procedure after receiving an active basal rate status change signaled by the Active Basal Rate Status Changed bit of the Flags field of IDD Status Changed characteristic (see Section 4.6).

4.10.2.5. Get Total Daily Insulin Status procedure

To get the total daily delivered bolus and basal insulin from midnight until now, the Collector shall write the Get Total Daily Insulin Status Op Code to the IDD Status Reader Control Point.

The Collector shall wait for the Get Total Daily Insulin Status Response Op Code indication with a Total Daily Insulin Status record indicating success of the operation as per the request or a Response Code Op Code indication with an error value as described in Section 4.15.5.

The received total daily insulin amounts refer to the current date time of the Insulin Delivery Sensor (i.e., if the date time is changed, the insulin amounts always refer to the current date time).

The Collector can use this procedure after receiving a total daily insulin status change signaled by the Total Daily Insulin Status Changed bit of the Flags field of the IDD Status Changed characteristic (see Section 4.6).

If the insulin delivery device does not support boluses, the Collector shall be able to handle a value of 0 for the Total Daily Insulin Sum of Bolus Delivered. If the insulin delivery device does not support a basal rate, the Collector shall be able to handle a value of 0 for the Total Daily Insulin Sum of Basal Delivered field (see IDD Features Flags in Section 4.9).

4.10.2.6. Get Counter procedure

To get the value of an internal counter of the insulin delivery device, the Collector shall write the Get Counter Op Code followed by a Counter Type and Counter Value Selection field to the IDD Status Reader Control Point.

The Collector shall wait for the Get Counter Response Op Code indication with a Counter record indicating success of the operation as per the request or a Response Code Op Code indication with an error value as described in Section 4.15.5.

The Counter Value Selection field of the Operand specifies the value of the Counter Value field contained in the response from the Sensor for the Get Counter procedure. For a Counter Value Selection set to Remaining, the Counter Value is the remaining time before the requested Counter Type expires. A negative value for the remaining time means the counter has already expired. In this case, the absolute value of the remaining time provides the time since expiration. For a Counter Value Selection set to Elapsed, the Counter Value is the elapsed time since the requested Counter Type started. The elapsed time value is never negative.

An insulin delivery device may have a restricted lifetime, warranty or loaner time. This procedure shall be used by a Collector to get the remaining or elapsed values of those counters.

4.10.2.7. Get Delivered Insulin procedure

To get the amounts of the delivered bolus and basal insulin, the Collector shall write the Get Delivered Insulin Op Code to the IDD Status Reader Control Point.

The Collector shall wait for the Get Delivered Insulin Response Op Code indication with a Delivered Insulin record indicating success of the operation as per the request or a Response Code Op Code indication with an error value as described in Section 4.15.5.

A Collector can use this procedure to get a delta of the delivered insulin by executing it periodically.

If an amount exceeds a value of 80,000.00 IU, a rollover will occur on the Insulin Delivery Sensor and the Collector will receive a delivered bolus or basal amount starting from 0.

The Collector shall accept a delivered bolus or basal amount set to 0 due to a rollover by the Server if an amount exceeds a value of 80,000.00 IU.

If the Collector was connected to the Insulin Delivery Sensor previously, the Collector can detect a rollover by checking if a retrieved amount is less than the one from the previous execution of this procedure. Depending on the implementation of the Collector, the frequency it executes this procedure and the insulin amount delivered, the Collector can determine that only one rollover has occurred.

4.10.2.8. Get Insulin On Board procedure

To get the amount and remaining duration of the Insulin On Board, which has been delivered by the insulin delivery device, the Collector shall write the Get Insulin On Board Op Code to the IDD Status Reader Control Point.

The Collector shall wait for the Get Insulin On Board Response Op Code indication with an amount of Insulin On Board indicating success of the operation as per the request or a Response Code Op Code indication with an error value as described in Section 4.15.5.

4.11. IDD Command Control Point

Before performing an IDD Command Control Point procedure, the Collector shall configure the IDD Command Control Point characteristic for indications and the IDD Command Data characteristic for notifications (all via the appropriate Client Characteristic Configuration descriptor).

If the Collector executes a procedure on the IDD Command Control Point which could require more than one response from the Insulin Delivery Sensor (e.g., Read Basal Rate Profile Template), the procedure may contain one or more IDD Command Data characteristic notifications between the write to this Control Point that began the procedure and the Response Code indication of this Control Point (CP) that ends the procedure.

4.11.1. IDD Command Control Point procedure requirements

Table 4.6 shows the requirements for the IDD Command control point procedures (Op Codes):

|

Procedure (Op Code) |

Section |

Requirements |

|||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Set Therapy Control State |

M |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Set Flight Mode |

M |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Snooze Annunciation |

M |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Confirm Annunciation |

M |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Read Basal Rate Profile Template[a] |

C.1 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Write Basal Rate Profile Template |

C.1 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Set TBR Adjustment |

C.2 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Cancel TBR Adjustment |

C.2 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Get TBR Template |

C.3 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Set TBR Template |

C.3 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Set Bolus |

C.4 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Cancel Bolus |

C.4 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Get Available Boluses |

C.4 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Get Bolus Template |

C.5 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Set Bolus Template |

C.5 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Get Template Status and Details |

C.6 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Reset Template Status |

C.6 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Activate Profile Templates |

C.7 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Get Activated Profile Templates |

C.7 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Start Priming |

O |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Stop Priming |

C.8 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Set Initial Reservoir Fill Level |

O |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Reset Reservoir Insulin Operation Time |

O |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Read ISF Profile Template[a] |

C.9 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Write ISF Profile Template |

C.9 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Read Insulin-to-Carbohydrate (I2CHO) Ratio Profile Template[a] |

C.10 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Write I2CHO Ratio Profile Template |

C.10 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Read Target Glucose Range Profile Template[a] |

C.11 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Write Target Glucose Range Profile Template |

C.11 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Get Max Bolus Amount |

O |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Set Max Bolus Amount |

O |

||||||||||||||||||||||||||||||||||||||||||||||||

|

[a] The Server sends one or more response records by notifications of the IDD Command Data characteristic. |

|||||||||||||||||||||||||||||||||||||||||||||||||

- C.1:

-

Mandatory if a basal rate is supported, otherwise excluded.

- C.2:

-

Mandatory if TBRs are supported, otherwise excluded.

- C.3:

-

Mandatory if TBR templates are supported, otherwise excluded.

- C.4:

-

Mandatory if boluses are supported, otherwise excluded.

- C.5:

-

Mandatory if bolus templates are supported, otherwise excluded.

- C.6:

-

Mandatory if a basal rate and/or TBR templates and/or bolus templates and/or ISF profile templates and/or I:CHO ratio profile templates and/or target glucose range profile templates are supported, otherwise excluded.

- C.7:

-

Mandatory if a basal rate and/or ISF profile templates and/or I:CHO ratio profile templates and/or target glucose range profile templates are supported, otherwise excluded.

- C.8:

-

Mandatory if optional procedure “Start Priming” is implemented, otherwise excluded.

- C.9:

-

Mandatory if ISF profile templates are supported, otherwise excluded.

- C.10:

-

Mandatory if I:CHO ratio profile templates are supported, otherwise excluded.

- C.11:

-

Mandatory if target glucose range profile templates are supported, otherwise excluded.

4.11.2. IDD Command Control Point behavioral description

4.11.2.1. Common Profile Template Reading procedures behavior

This section defines the common behavior of the following IDD Command control point procedures to read profile templates. These are templates of a series of time blocks that define a specific therapy setting. Each time block contains such a therapy setting to be applied for a specific duration:

-

Read Basal Rate Profile Template procedure (see Section 4.11.2.7)

-

Read ISF Profile Template procedure (see Section 4.11.2.26)

-

Read I2CHO Ratio Profile Template procedure (see Section 4.11.2.28)

-

Read Target Glucose Range Profile Template procedure (see Section 4.11.2.30)

Before reading a profile template the Collector should ensure that this template is configured (see Section 4.11.2.18).

Depending on the number of time blocks of a profile, the entire profile (i.e., all defined time blocks of that profile) could be sent in several steps by one or many responses of the Server (i.e., in each step the IDD Command Data characteristic is notified, see Section 4.12). The Collector shall wait for the corresponding response Op Code notification (e.g., Read Basal Rate Profile Template Response) of the IDD Command Data characteristic for each response with a Profile Template record indicating success of the current step as per the request (i.e., the receipt of a Profile Template record containing one or several time blocks). Finally, the Collector shall wait for the corresponding Response Code Op Code indication (e.g., Request Op Code set to Read Basal Rate Profile Template and Response Code set to Success) of the IDD Command Control Point indicating success of the operation (i.e., the receipt of the complete profile). In case of an error, the Collector shall be able to handle a Response Code Op Code indication with an error value as described in Section 4.15.5.

4.11.2.2. Common Profile Template Writing procedures behavior

This section defines the common behavior of the following IDD Command control point procedures to write profile templates (also see Section 4.11.2.1 for an explanation of profile templates and their time blocks):

-

Write Basal Rate Profile Template procedure (see Section 4.11.2.8)

-

Write ISF Profile Template procedure (see Section 4.11.2.27)

-

Write I2CHO Ratio Profile Template procedure (see Section 4.11.2.29)

-

Write Target Glucose Range Profile Template procedure (see Section 4.11.2.31)

Before writing a profile template the Collector should ensure that this template is configurable (see Section 4.11.2.18) and that the number of time blocks does not exceed the maximum number of supported time blocks for that profile (see Get Template Status and Details procedure in Section 4.11.2.18).

Depending on the number of time blocks of a profile, the profile may be sent in several steps by one or many executions of this procedure (i.e., in each step a Profile Template record containing one or several time blocks is sent). The Collector shall use the First Time Block Number Index field of the Profile Template record to specify the index of the time blocks to be sent within the entire profile. The Collector should ensure that the First Time Block Number Index field as well as the total number of time blocks do not exceed the maximum number of supported time blocks (see Get Template Status and Details procedure in Section 4.11.2.18) and that the First Time Block Number Index field is not less than 1.

The Collector initiates a transaction (i.e., to send the first time blocks of the profile) with the first write of the Op Code of the procedure to the IDD Command control point. The bit 0 (End Transaction) of the Flags field shall be set to False except in the last procedure of the transaction when it shall be set to 1 (also see Section 4.15.3).

The Collector shall wait for a corresponding Response Op Code indication (e.g., Write Basal Rate Profile Template Response) after each execution of the procedure with a Flags field, a Profile Template Number field and a First Time Block Number Index field indicating success of the current step as per the request. When the Collector executes the procedure to send the last time block or time blocks of the profile, the Collector shall wait for a corresponding Response Op Code indication (e.g., Write Basal Rate Profile Template Response) with a Flags field with bit 0 set to 1 (Transaction Completed) and a Profile Template Number field as well as a First Time Block Number Index field indicating the success of the operation (i.e., the complete write of the profile). As soon as a template is written successfully by the Collector, its status is set to Configured by the Insulin Delivery Sensor.

If the Collector writes a profile template to the IDD Command Control Point and the profile template fails the plausibility check on the Insulin Delivery Sensor, it will receive a Response Code CP indication with the Response Code Value set to Plausibility check failed (also see Section 3.7.2.1.2 in [1]).

In case of an error the Collector shall be able to handle a Response Code Op Code indication with an error value as described in Section 4.15.5. In addition, the Collector may restart the transaction and may send the entire profile again.

4.11.2.3. Set Therapy Control State procedure

To set the therapy state of the insulin delivery device, the Collector shall write the Set Therapy Control State Op Code followed by a Therapy Control State field to the IDD Command Control Point.

The Collector shall wait for the Response Code Op Code indication with Response Code Value set to Success indicating success of the operation as per the request or an error value as described in Section 4.15.5.

4.11.2.4. Set Flight Mode procedure

To activate the flight mode of the insulin delivery device, the Collector shall write the Set Flight Mode Op Code to the IDD Command Control Point. The flight mode places the insulin delivery device to a mode accepted by the avionic authorities to allow inflight usage.

The Collector shall wait for the Response Code Op Code indication with Response Code Value set to Success indicating success of the operation as per the request or an error value as described in Section 4.15.5.

4.11.2.5. Snooze Annunciation procedure

To snooze an annunciation of the Insulin Delivery Sensor, which is expected to still be active until it is confirmed, the Collector shall write the Snooze Annunciation Op Code followed by an Annunciation Instance ID field to the IDD Command Control Point.

The Collector shall wait for the Snooze Annunciation Response Op Code indication with an Annunciation Instance ID field indicating success of the operation as per the request or a Response Code Op Code indication with an error value as described in Section 4.15.5.

The Collector should be able to handle the following changes of characteristic values as soon as this procedure is executed successfully:

-

The Annunciation Status Changed bit of the Flags field of the IDD Status Changed characteristic (see Section 4.6) will be set to 1

-

If this annunciation is made available in the IDD Annunciation Status characteristic (i.e., if there is no higher priority annunciation), the Annunciation Status field will be set to a value of Snoozed

If the snoozing time (its value is left to the implementation of the Insulin Delivery Sensor) is over, the Collector should be able to handle the following changes of characteristic values:

-

The Annunciation Status Changed bit of the Flags field of the IDD Status Changed characteristic (see Section 4.6) will be set to 1 or stays 1 if it was not reset by the Collector (see Section 4.10.2.1)

-

If this annunciation is made available in the IDD Annunciation Status characteristic (i.e., if there is no higher priority annunciation), the Annunciation Status field will be set to a value of Pending

4.11.2.6. Confirm Annunciation procedure

To confirm an annunciation of the Insulin Delivery Sensor, the Collector shall write the Confirm Annunciation Op Code followed by an Annunciation Instance ID field to the IDD Command Control Point.

The Collector shall wait for the Confirm Annunciation Response Op Code indication with an Annunciation Instance ID field indicating success of the operation as per the request or a Response Code Op Code indication with an error value as described in Section 4.15.5.

After successful execution of this procedure, the Collector should be able to handle that the Annunciation Status Changed bit of the Flags field of the IDD Status Changed characteristic (see Section 4.6) will be set to 1.

After the Collector successfully executes the Confirm Annunciation procedure, the IDD Annunciation Status characteristic does not provide information about that annunciation.

4.11.2.7. Read Basal Rate Profile Template procedure

To read a basal rate profile template of the Insulin Delivery Sensor, the Collector shall write the Read Basal Rate Profile Template Op Code followed by a Basal Rate Profile Template Number field to the IDD Command Control Point.

For the Read Basal Rate Profile Template procedure the common behavior of reading profile templates apply (see Section 4.11.2.1).

4.11.2.8. Write Basal Rate Profile Template procedure

To write a basal rate profile template to the Insulin Delivery Sensor, the Collector shall write the Write Basal Rate Profile Template Op Code followed by a Basal Rate Profile Template record to the IDD Command Control Point.

For the Write Basal Rate Profile Template procedure the common behavior of writing profile templates apply (see Section 4.11.2.2).

4.11.2.9. Set TBR Adjustment procedure

To set a new or change a currently active temporary basal rate, the Collector shall write the Set TBR Adjustment Op Code followed by a TBR record to the IDD Command Control Point.

The Collector shall wait for the Response Code Op Code indication with Response Code Value set to Success indicating success of the operation as per the request or an error value as described in Section 4.15.5.

If the Insulin Delivery Sensor supports TBR templates (see IDD Features Flags in Section 4.9), the Collector can set a TBR adjustment from a stored TBR template by attaching the TBR Template Number field in the TBR record with the value of the TBR template number to set and then shall indicate its presence by setting bit 0 of the Flags field to True (TBR Template Number Present). In this case the Insulin Delivery Sensor will use the settings of the corresponding TBR template denoted by the TBR Template Number field and ignore the values of the fields that are available in that TBR template. The Collector can read the TBR settings of that template before executing this procedure (see Section 4.11.2.11). Furthermore, before applying this TBR template the Collector should ensure that it is configured (see Section 4.11.2.18).

If the settings of a currently active TBR are to be changed (i.e., the settings are to be overwritten completely), the Collector shall set bit 2 of the Flags field to True (Change TBR). If otherwise there is currently no active TBR and a TBR shall be activated, the Collector shall set this bit to False.

4.11.2.10. Cancel TBR Adjustment procedure

To cancel a currently active TBR, the Collector shall write the Cancel TBR Adjustment Op Code to the IDD Command Control Point.

The Collector shall wait for the Response Code Op Code indication with Response Code Value set to Success indicating success of the operation as per the request or an error value as described in Section 4.15.5.

4.11.2.11. Get TBR Template procedure

Before getting a TBR template the Collector should ensure that this template is configured (see Section 4.11.2.18).

To get the parameters of specific TBR Template of the Insulin Delivery Sensor, the Collector shall write the Get TBR Template Op Code followed by a TBR Template Number field to the IDD Command Control Point.

The Collector shall wait for the Get TBR Template Response Op Code indication with a TBR Template record indicating success of the operation as per the request or a Response Code Op Code indication with an error value as described in Section 4.15.5.

4.11.2.12. Set TBR Template procedure

Before setting a TBR template the Collector shall ensure that this template is configurable (see Section 4.11.2.18).

To set the parameters of specific TBR Template of the Insulin Delivery Sensor, the Collector shall write the Set TBR Template Op Code followed by a TBR Template record to the IDD Command Control Point.

The Collector shall wait for the Set TBR Template Response Op Code indication with a TBR Template Number field indicating success of the operation as per the request or a Response Code Op Code indication with an error value as described in Section 4.15.5.

4.11.2.13. Set Bolus procedure

Before setting a bolus, the Collector can check if a bolus of a specific type is currently available by using the Get Available Boluses procedure (see Section 4.11.2.15).

To set a bolus, the Collector shall write the Set Bolus Op Code followed by a Bolus record to the IDD Command Control Point.

The Collector shall wait for the Set Bolus Response Op Code indication with a Bolus ID field of the new set bolus indicating success of the operation as per the request or a Response Code Op Code indication with an error value as described in Section 4.15.5.

If the Collector sets a bolus and the specified type is currently not available on the Insulin Delivery Sensor, it will receive a Response Code CP indication with the Response Code Value set to Maximum Bolus Number reached.

If the Insulin Delivery Sensor supports a bolus delay time (see IDD Features Flags in Section 4.9), the Client can attach the Bolus Delay Time field in the Bolus record and then shall indicate its presence by setting bit 0 of the Flags field to True (Bolus Delay Time Present).

If the Insulin Delivery Sensor supports bolus templates (see IDD Features Flags in Section 4.9), the Client can set a bolus from a stored bolus template by attaching the Bolus Template Number field in the Bolus record with the value of the bolus template number to set and then shall indicate its presence by setting bit 1 of the Flags field to True (Bolus Template Number Present). In this case the Insulin Delivery Sensor will use the settings of the corresponding Bolus template denoted by the Bolus Template Number field and ignore the values of the fields that are available in that bolus template. The Collector can read the bolus parameters of that template by executing the Get Bolus Template procedure before setting a bolus (see Section 4.11.2.16). In addition, the Collector should ensure that this bolus template is configured (see Section 4.11.2.18).

If the Insulin Delivery Sensor supports a bolus activation type (see IDD Features Flags in Section 4.9), the Client can attach the Bolus Activation Type field in the Bolus record and then shall indicate its presence by setting bit 2 of the Flags field to True (Bolus Activation Type Present).

If the Collector sets the Bolus Type to “Extended” in the Operand, it should set the Bolus Fast Amount field to 0, or otherwise it will receive an error.

If the Collector sets the Bolus Type to “Fast” in the Operand, it should set the Bolus Extended Amount and Bolus Duration fields to 0, or otherwise it will receive an error.

4.11.2.14. Cancel Bolus procedure

To cancel a set bolus, the Collector shall write the Cancel Bolus Op Code followed by a Bolus ID field to the IDD Command Control Point.

The Collector shall wait for the Cancel Bolus Response Op Code indication with a Bolus ID field of the canceled bolus indicating success of the operation as per the request or a Response Code Op Code indication with an error value as described in Section 4.15.5.

4.11.2.15. Get Available Boluses procedure

To check which bolus types are currently available, the Collector shall write the Get Available Boluses Op Code to the IDD Command Control Point.

The Collector shall wait for the Get Available Boluses Response Op Code indication with a Flags field of the available bolus types indicating success of the operation as per the request or a Response Code Op Code indication with an error value as described in Section 4.15.5.

The Collector should use this procedure before executing the Set Bolus procedure (see Section 4.11.2.13).

4.11.2.16. Get Bolus Template procedure

Before getting a bolus template the Collector should ensure that this template is configured (see Section 4.11.2.18).

To get the parameters of a bolus template, the Collector shall write the Get Bolus Template Op Code followed by a Bolus Template Number field to the IDD Command Control Point.

The Collector shall wait for the Get Bolus Template Response Op Code indication with a Bolus Template record indicating success of the operation as per the request or a Response Code Op Code indication with an error value as described in Section 4.15.5.

The Collector should use this procedure before setting a bolus based on a bolus template (see Section 4.11.2.13).

4.11.2.17. Set Bolus Template procedure

Before setting a bolus template the Collector should ensure that this template is configurable (see Section 4.11.2.18).

To set the parameters of a bolus template, the Collector shall write the Set Bolus Template Op Code followed by a Bolus Template record to the IDD Command Control Point.

The Collector shall wait for the Set Bolus Template Response Op Code indication with a Bolus Template Number field of the set bolus template indicating success of the operation as per the request or a Response Code Op Code indication with an error value as described in Section 4.15.5.

If the Insulin Delivery Sensor supports a bolus delay time (see IDD Features Flags in Section 4.9), the Client can attach the Bolus Delay Time field in the Bolus record and then shall indicate its presence by setting bit 0 of the Flags field to True (Bolus Delay Time Present).

If the Collector sets the Bolus Type to “Extended” in the Operand, it shall set the Bolus Fast Amount field to 0. If the Collector sets the Bolus Type to “Fast” in the Operand, it shall set the Bolus Extended Amount and Bolus Duration fields to 0.

4.11.2.18. Get Template Status and Details procedure

To get the status and details of all supported templates (i.e., if they are configured and / or configurable, maximum number of supported time blocks, starting template number and number of templates), the Collector shall write the Get Template Status and Details Op Code to the IDD Command Control Point.

The Collector only can read (e.g., Read Basal Rate Profile procedure, see Section 4.11.2.7), apply (e.g., Set Bolus procedure or Activate Profile Templates procedure, see Sections 4.11.2.13 and 4.11.2.20 respectively) and reset (see Section 4.11.2.19) configured templates. Otherwise the corresponding procedure will return an error. If a template is written by the Collector, then its status is set to Configured by the Insulin Delivery Sensor. The Collector shall use this procedure to check if a template is configured before reading, applying or resetting a template.

The Collector only can write configurable templates. Otherwise the corresponding procedure will return an error. Templates that are not configurable might be predefined by the Insulin Delivery Sensor and then cannot be changed by the Collector (i.e., the template is not configurable, but it is configured, because it is set by the Insulin Delivery Sensor). The Collector shall use this procedure to check if a template is configurable before writing a template.

The Collector may use this procedure to only present templates in a UI that are configured in case of reading and applying templates or that are configurable in case of writing templates.

The maximum number of supported time blocks for a Profile Template type defines the maximum number of time blocks the Collector can set for that Profile Template type when writing a template (e.g., basal rate profile template).

The starting template number and number of templates are used to determine the template number range for a template type. Each supported template type has a defined range of unique template numbers such that a template can be referred to with only its template number. For example, if the basal rate profile template type has a starting template number set to 1 and number of templates set to 3, then template numbers 1, 2, and 3 identify basal rate profile templates, and these template numbers cannot be used to identify a template of another template type.

Depending on the number of template types supported, all the template details could be sent in one or many responses of the Server. The Collector shall wait for the Get Template Status and Details Response Op Code notification of the IDD Command Data characteristic for each supported template type with a template status and details record. Once all the template status and details records have been reported for all supported template types, the Collector shall wait for the corresponding Response Code Op Code indication with Request Op Code set to Get Template Status and Details and Response Code set to Success of the IDD Command Control Point indicating success of the procedure. In case of an error the Collector shall be able to handle a Response Code Op Code indication with an error value as described in Section 4.15.5

4.11.2.19. Reset Template Status procedure

To reset the status of one or many templates (i.e., marking it or them as “not configured”), the Collector shall write the Reset Template Status Op Code followed by a Number of Templates to Reset field and a Template Numbers field to the IDD Command Control Point.

The Collector shall wait for the Reset Template Status Response Op Code indication with a Number of Templates Reset field and a Template Numbers field of the reset templates indicating success of the operation as per the request or a Response Code Op Code indication with an error value as described in Section 4.15.5.

The Collector can only reset templates that are both configurable and configured (see Section 4.11.2.18), otherwise this procedure will return an error. In addition, an active basal rate profile template, an ISF profile template, an I:CHO ratio profile template, or target glucose range profile template cannot be reset if it is in use by the Sensor Application (e.g., by a bolus calculator).

The Collector may use this procedure to remove one or more templates within a UI from a list of readable or usable templates (i.e., the UI could only show the configured templates).

4.11.2.20. Activate Profile Templates procedure

Before activating a profile template, the Collector should ensure that it is configured (see Section 4.11.2.18).

To activate profile templates on the Insulin Delivery Sensor, the Collector shall write the Activate Profile Templates Op Code followed by a Number of Profile Templates to Activate field and a Profile Template Numbers field identifying the profile templates to activate to the IDD Command Control Point.

The Collector shall wait for the Activate Profile Templates Response Op Code indication with a Number of Profile Templates Activated field and a Profile Template Numbers field indicating success of the operation as per the request or an error value as described in Section 4.15.5.

Once a basal rate profile template is activated, it cannot be deactivated, but the Collector can activate another basal rate profile template or, if the active basal rate profile is configurable, set the basal rate of the active basal rate profile template to 0 IU/h.

Once an ISF, an I:CHO ratio, or a target glucose range profile template is activated, it cannot be deactivated, but the Collector can activate another profile template of that type.

4.11.2.21. Get Activated Profile Templates procedure

To get all the currently activated profile templates, the Collector shall write the Get Activated Profile Templates Op Code to the IDD Command Control Point.

The Collector shall wait for the Get Activated Profile Templates Response Op Code indication with a Number of Activated Profile Templates field and a conditional Profile Template Numbers field indicating success of the operation as per the request or a Response Code Op Code indication with an error value as described in Section 4.15.5.

The Collector may use this procedure to get the activated profile templates which have been activated by another Collector.

The Collector shall be able to handle the following responses:

-

If no profile templates are activated on the Server, the Number of Activated Profile Templates field value is 0 and the Activated Profile Template Numbers field is not included in the response.

-